how to tell what gen a 396 cu in motor is

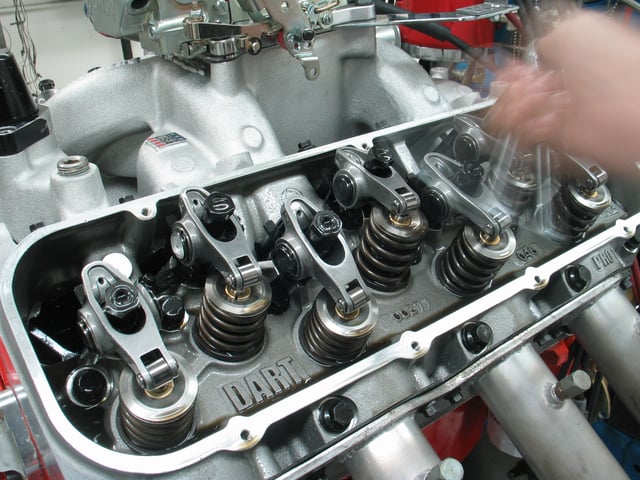

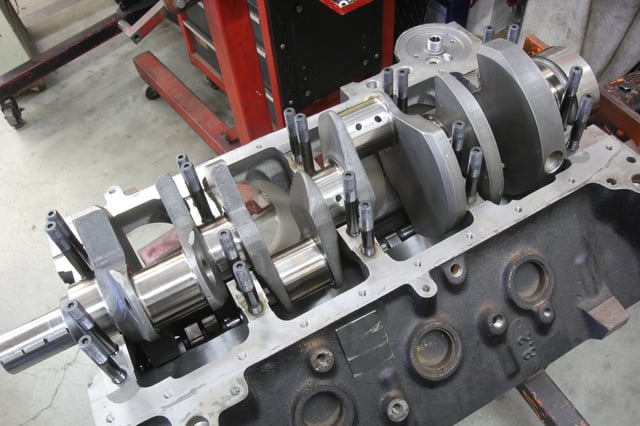

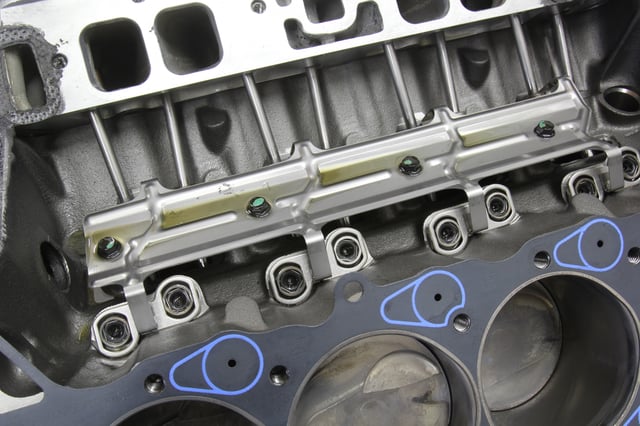

"The big block Chevy is one of the most raced engine platforms in motorsports. We've compiled some history and a massive library of parts bandy knowledge into a comprehensive resource. Read on!" The large-block Chevy goes by many names – the Rat, the Porcupine, and if you get back far plenty, the semi-hemi. It started life equally a major upgrade from the 348/409 W motor. What eventually became the MKIV first appeared equally the Mystery Engine at the 1963 Daytona 500. The debut was both promising but ultimately inauspicious. The Mystery Engine made far more horsepower than its large-cake '60s contemporaries like the 427 FE Ford, simply nearly all failed either in qualifying, practice or the 500-mile race. None finished. Chevrolet recalled all but a couple of these engines and returned in 1965 with fully adult 396 and 427ci production engines whose present-day versions now are ubiquitous and take pushed the displacement "bulwark" far beyond 700 cubic inches. For this story, we'll concentrate on the production engine lineage of this highly-successful engine family tracing its heritage from the earliest to the well-nigh gimmicky while offering information on interchangeability. In fact, this ability to exchange components between displacements that are oft separated by five decades of casting dates is perhaps the keynote of both the pocket-size- and big-block Chevys. With but a few exceptions, interchanging parts and the huge tonnage of aftermarket parts availability makes the Rat motor a true survivor. While the majority of big-blocks displaced 454 inches, Chevy did build a production engine displacing 496ci. Just the hereafter of the Rat appears to be stroker versions and today you could easily build a stock deck height Rat motor at 500-plus-ci using off-the-shelf parts. Displacement The primeval product large-block Chevy appeared as the 396 and bolted into the new-for-'65 total-size Impalas as well as in the Corvette. There were even a precious few '65 Z-16 SS396 Chevelles built in 1965. This was enhanced in 1966 with multiple horsepower combinations of the 427 as high equally 425 horsepower. Past 1970, the 396 had grown to 402 inches with a 0.030-inch overbore (although however badged as the SS 396 in the Chevelle) but was overshadowed past the introduction of the 454. These engines were labeled as Marking 4 versions, the fourth in the developmental lineage that could be traced all the way back to the late '50s 348/409 engines. In fact, the MK IV shares the same bore spacing and main web position with its W-motor ancestor although the big-block principal journal is roughly 0.250-inch larger in diameter. Minor changes to accommodate a one-slice rear primary seal and hydraulic roller lifters occurred with the advent of the Gen V and later the Gen VI engines in the 1990s. Even with Gen V/VI revisions, the 454'due south deportation remained constant for decades until GM radically changed the large-block, pushing a production heavy-duty truck engine up to 8.1 liters (496ci) that appeared in 2001. The bore remained at 4.250 but the stroke increased from 4.00- to a hefty 4.37-inches. Unfortunately for interchange artists, GM changed virtually everything in the engine and then parts compatibility ended with this 8.1L. It'due south better to call back of the 8.1L every bit a completely different engine and not in the same lineage equally the remainder of the big-cake lineup. Even bigger yet was the 502ci Rat that is worth mentioning even though it never appeared in a production GM vehicle. Sold through Chevrolet Performance, this is a later on model Gen VI engine sporting a serious 4.500-inch bore, which opens up bully potential for multiple big-inch, bore-stroke combinations. We'll decompress the Rat into its major components to give you an thought of how each of these parts fit into the overall big-block concatenation of deportation and power opportunities. While the modest-cake Chevy has been overshadowed now by the LS family, the big-block Chevy is still the best approach for building a big cubic inch GM engine for the street. Blocks The one consequent factor throughout the entire evolution of the large-cake Chevy has been its bore spacing. All big-blocks utilize the same four.840-inches of altitude between the cylinder centerlines. This dimension has remained fixed until you go into custom five.00-inch bore spacing blocks from companies such every bit Dart Machinery that are nigh often synthetic as pure competition engines. The manufacturing plant bore spacing is broad enough to hands accommodate four.50- and even iv.60-inch bores that notwithstanding create sufficient room between the cylinders for adequate caput gasket sealing and engine cooling. From a production standpoint, GM but built iron blocks with one exception – the 1969 ZL1 427 engine congenital for the Corvette and COPO Camaros. This was an exotic (for the time) all-aluminum engine and a major difference for GM. Today, the best place to find an aluminum block would be the aftermarket, like Sprint. Block applied science has improved to the point now where the simply bulwark to running an all-aluminum Rat would be the cost of entry. The original MK IV blocks used the traditional ii-slice rear main seal technique from 1965 continuously until the Gen V engines appeared in 1991 that moved to the jumpsuit rear seal configuration. This is one of several big changes for these cylinder blocks with the Gen V and later Gen 6 versions in 1996. Along with the rear main, the Gen V modified the head gasket sealing configuration, added hydraulic roller lifers, revised the oil pan gasket to a jumpsuit, and reconfigured the front timing chain cover commodities patterns. The Gen V conversion to hydraulic roller lifters likewise effected revisions to the lifter valley with taller cast-in lifter bores needed to accommodate the increased elevation of the roller lifters. The lifter valley also incorporated a few minor additions of dogbones and a sail metal "spider" to retain the lifters that we'll illustrate in the accompanying photo. The practiced news is that these later blocks maintained the original block deck height, bellhousing and motor mountain bolt patterns so swapping between older and newer generation blocks is relatively elementary. There are some pocket-sized differences, still. The Gen V production blocks were designed for EFI consecration systems then the Gen V production blocks did not include a mechanical fuel pump boss nor the cast-in location for the stock cross-shaft for mechanical clutch linkage. If these are critical, aftermarket versions of these blocks are bachelor from Dart that easily conform these additions. A major Rat motor benefit is its clangorous crankcase that can easily adapt big stroke increases with virtually no block modifications. This happens to exist a 4.l-inch Gen Six block being fitted with a four.250-inch stroke crank to build a 540. Crankshafts Factory crankshafts were offered in both cast and forged versions although cast versions are clearly the most common. All the early on 1965 through 1969 engines were also configured as internally balanced engines. This means that both the harmonic balancer and flywheel/flexplate were neutral balance. This changed in 1970 with the 454 as Chevrolet moved external offset weight to both ends of the crankshaft. This means that these externally counterbalanced cranks required a flywheel/flexplate and harmonic balancer fitted with offset weight in a specific location. These components must non exist interchanged with the internally balanced components. Furthermore, when GM created the Gen V, one-piece rear main seal block this demanded a different crankshaft rear master seal. Since the offset flexplate/flywheel mounting flange could no longer accept that small beginning weight, the external balance number for the flexplate/flywheel increase from the 2-piece rear main seal's 33 ounce-inch (oz-in) value to the Gen V value of 42.5 oz-in. Information technology's critical to know which internal or externally-balanced engine you have when adapting big-blocks to different vehicles because of these differing external balance values. Making all this even more potentially disruptive is that within these iii different flexplate/flywheel combinations the crankshaft commodities blueprint remains the same. So just because the flexplate/flywheel bolts to the engine doesn't mean the correct bike is in place. Connecting Rods The connecting rod story is thankfully far less convoluted. There are basically two main factory connecting rods and the difference really comes down to rod commodities size. There are many other modest differences, but the starting time large-cake half-dozen.135-inch length versions were fitted with 3/8-inch rod bolts. The major upgrade presently followed with high performance 396 and 427 and all subsequent performance engines using a 7/xvi-inch commodities. Well-nigh production large-block rods were of the pressed-pin multifariousness meaning that the wrist pin was pressed into the modest stop of the connecting rod. But fifty-fifty some early on operation engines switched to a full floating organization with a bushing in the small end of the rod. In mild performance applications, stock rods exercise a fine job. Only in a serious application where engine speeds exceeding 6,500 can be expected, an aftermarket 4340 forged steel I- or H-beam rod is a prudent investment. Rods don't make horsepower, but a failed rod tin crusade catastrophic damage and is hardly worth the run a risk. By the time a stock rod is Magnaflux tested for cracks, shot-peened, new ARP rod bolts fitted, and resized – that investment is not far from the toll of a much stronger set of aftermarket rods. Cylinder Heads Over the decades, the large-block has experienced a raft of various product cylinder head variations. The earliest heads came in both cast atomic number 26 and aluminum but employed what is now called a closed combustion chamber. The tight chambers shrouded the small valves and by 1970, 2nd generation heads were blessed with a larger, open chamber structure that immune upward to 2.250-/1.88-inch valves. While combustion chamber size and configuration is of import, most enthusiasts tend to focus on intake port configuration. Here, Chevrolet offered ii variations –oval and the rectangle. Oval port heads were aimed at base engine packages while the rectangle port heads were reserved for the performance engines. Later, some heavy-duty truck engines were fitted with what are now called peanut port heads which is a clue as to their miniscule inlet opening. The all-time of the iron oval port, open up-chamber heads are the casting number 353049 versions that when upgraded with larger 2.25-/1.88-inch valves and some very minor port work can deliver impressive power. Of course, the downward side is that they're massively heavy. Nigh performance seekers will opt for whatsoever number of aftermarket aluminum heads like those from Dart. There are various chamber, valve, intake runner, and valve leap options that will fit well-nigh whatever application. In terms of interchangeability, the biggest concern is sleeping room compatibility with the pistons and ensuring the pinch ratio meets your needs. One matter to keep in mind is that closed bedchamber heads cannot be used on an engine with domed, open chamber pistons considering the dome will physically hit the head. This isn't a business with flat elevation or dished pistons but is a hard and fast dominion with domed pistons. Conversely, a domed closed-bedchamber piston engine can accept open up chamber heads without interference. The divergence in sleeping accommodation size can push the pinch in an unintended management if not matched properly so that's an area to go on in mind. For case, tossing a set of 454 open-sleeping room heads on a 396 could radically reduce the compression ratio because of the roughly 10cc larger bedchamber on a short-stroke engine. Camshafts Product large-blocks all the manner into the mid '90s were ever apartment tappet camshaft engines. When GM converted to the Gen 5, the big modify was fitting the new big-block with hydraulic roller lifter camshaft. This was mainly aimed at reducing engine friction that promised meliorate fuel mileage. At showtime the hydraulic roller was scoffed at, but today's high quality lifters tin can at present evangelize on serious 700 to 800 hp packages using an improved version of these original hydraulic rollers. This movement not only changed the style of the lifter but as well how the cam was retained. When converting flat tappet big-blocks over to a roller requires the use of a button that contacts the inside timing cover to foreclose the cam from moving forward. Gen Five and VI engines use a steel retaining plate over the cam which requires a stepped nose on the camshaft and a different cam gear. This move to hydraulic rollers also made a modify to the rocker arm assembly. From the earliest days, big-blocks like their small-block cousins were fitted with individual stud-mounted rockers that required adjusting the installation preload. The factory hydraulic roller lifters also converted to what is called a net lash system where a rocker arm bolt tightens the stamped steel rocker in a set position. This pattern uses pushrod length to set the proper lifter preload. There are kits bachelor to catechumen these heads over to adjustable roller rockers. Intakes With both oval and rectangle port big-cake cylinder heads, this dictates that the intake manifold port must also match the cylinder head port configuration. The bolt pattern between these two heads are the aforementioned, so in a compression it is possible to run an oval port manifold on a rectangle port engine and, opposite to what most forum experts will proclaim, there really isn't a major performance deposition. Product big-block intakes are, for the most part, uninspired simply the aftermarket has yous covered for either oval or rectangle port engines in both dual plane and unmarried airplane versions. Determination In the interest of brevity, this attempt has just covered the crest of the monster wave of data bachelor for production large-cake Chevy street engines. Opportunities abound to build a big cubic inch street motor that even normally aspirated has the grunt to brand an impressive street engine.

Topics: ENGINE BUILDS, CHEVY, featured, ENGINE TECH, Tech

scottprothervents.blogspot.com

Source: https://blog.dartheads.com/everything-you-wanted-to-know-about-the-big-block-chevy-engine

0 Response to "how to tell what gen a 396 cu in motor is"

Post a Comment